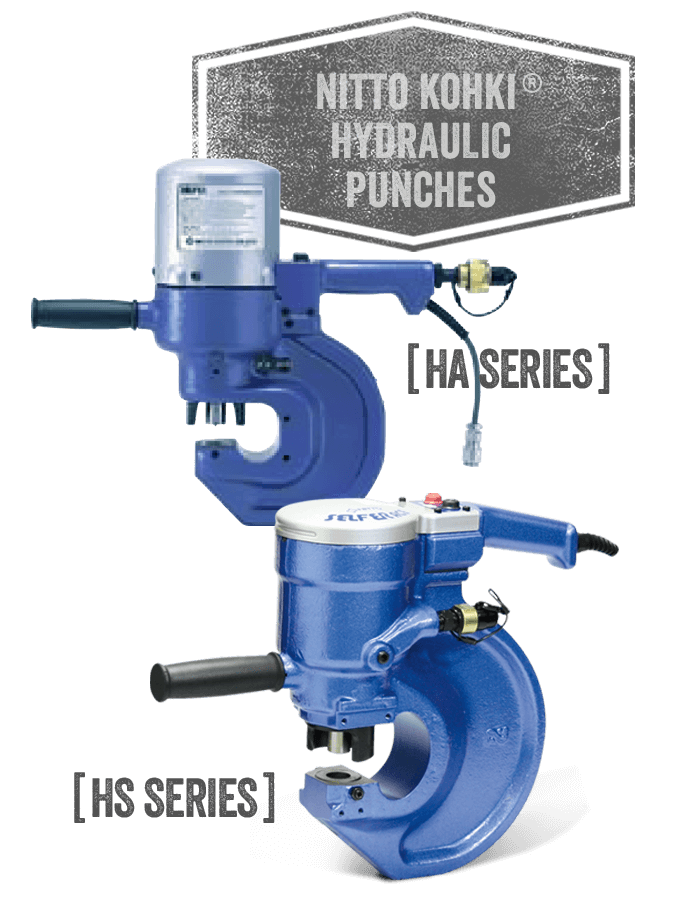

Hydraulic Punches 5000 Psi

This portable hydraulic punching unit, which weighs in at just 31 pounds, punches in a matter of seconds and is lightweight at only 31 pounds. The dual-action stripper holds and removes material as you punch. It can punch bus bars, tower iron and railings with a maximum tensile force of 65,000 psi. Mount it on your bench or transport it to the jobsite. In 24 hours, rectangular, square and hex tools will be available.

Our range of this machine can swiftly punch various special-shaped holes like round and oblong holes. It also features a backup switch that stops the punch immediately at any time. This single-acting hydraulic has a compact design powered by a hydraulic pump but has manual and electric hydraulic pump options( you can select any one based on your industry needs).